Blanchard Contour cutaway

Here's a brief description of how I do my contoured cutaway.

I work on an adjustable workboard rather than a traditional mold. I think it is probably easier to do these contoured cutaways on this type of workboard. Working in a conventional mold will require some modifications.

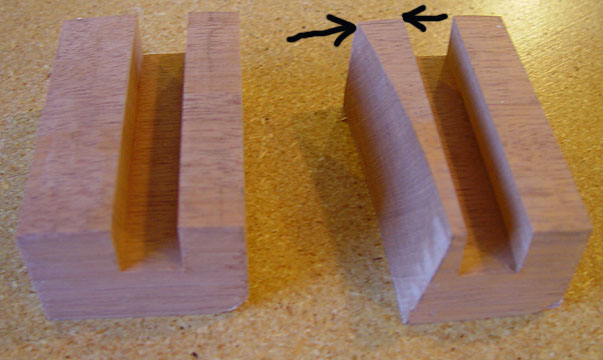

Here is a blank neck block and one that has been shaped. I use a 3/4" X 3/4" mortice and tennon joint.

The mortice is precut into the block. Notice that there is extra width on the cutaway side so that there will be enough wood to reach all the way over to the side as it curves away from the block on the inside of the guitar.

The block on the right has been shaped. The dimension indicated is critical l!!! It must be the proper width to make the side line up with the edge of the fingerboard. Don't forget to account for the thickness of the side.

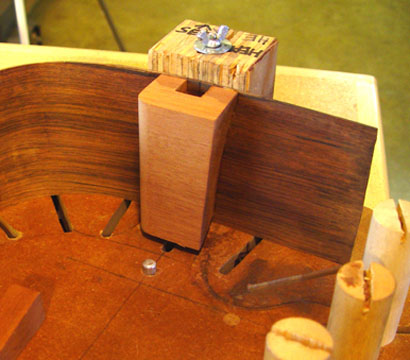

Here, the shaped block has been glued to the non-cutaway side. Doing this first helps hold the neck block square. I glue it right over the mortice and then cut the mortice open later.

There is a lot going on in this picture. There is a block running down the center of the guitar and a clamp pressing the neck block against it. This helps hold the neck block in position while the other side is positioned and clamped. The contoured area of the cutaway has been heated with a heat gun, and then clamped down tight on the neck block with a big C clamp and a contoured, flexible block (polyurethane). Previously the side had been bent to shape as if the cutaway was not going to be contoured.

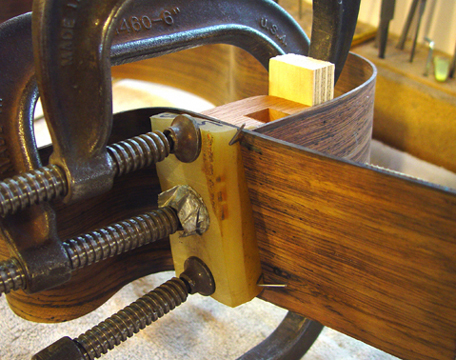

After moving the side around to align it properly, I drill two small holes for locating pins, through the side and into the neck block. Make sure you put these pins in places that will either be cut off or covered up by binding later.

In order to reduce the chance of the side splitting when bent across the grain, I superglue a piece of mesh drywall tape on to the excess side. This REALLY helps avoid splitting!!

I take the sides out of the mold to do the actual glue up. It is much easier to get the clamps on this way.The pins maintain alignment so the mold is not needed at this point.